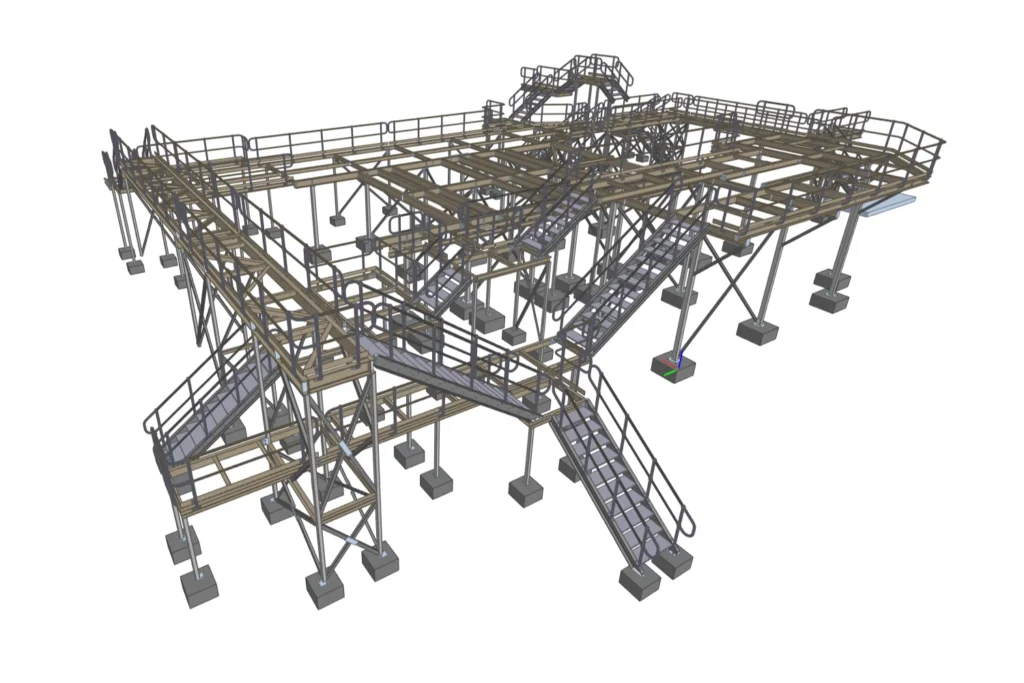

Structural Steel

Our production revolves around structural steel, meticulously crafted by our skilled fabricators and welders in our well-equipped workshops, adhering strictly to the highest standards. Every component is carefully painted to match your specifications precisely. Our installation and erection services are supported by a proficient in-house team that is extensively trained and experienced.

Additionally, our project managers work closely with clients and project partners to ensure that all construction, installation, and commissioning activities are performed exceptionally, consistently exceeding client expectations.

Processed Beam Supply

We’re thrilled to unveil the installation of our state-of-the-art Ficep Plasma Beamline at IFC Steel.

Housed within our newly expanded workshop, this robotic plasma beamline opens up a world of structural steel processing options for our local and national customers, boasting unparalleled accuracy and efficiency.

Our advanced plasma beamline can cut and process various steel products, including structural beams, plates, tubes, and merchant bars. We are ready to supply customers with semi-finished components for final fabrication and installation.

With this innovative addition, our team is ready to offer your business a comprehensive solution encompassing top-notch products and expert processing, ensuring your next project is delivered on time and to exact specifications.

Design

IFC Steel stands as your reliable partner from project inception, guiding your company through every step. Our involvement commences in the design phase, collaborating closely with engineers and architects for a seamless journey from concept to completion.

With an in-house team boasting hands-on experience in fabrication and building erection, IFC Steel holds a comprehensive understanding of the structural steel industry. Leveraging cutting-edge 3D Modeling software, including Advance Steel, Revit, and Tekla, we are fully equipped to manage projects ranging from 1 ton to 1000 tons and beyond.

We produce superior structural steel fabrication drawings tailored to meet the demands of architectural, seismic, structural, and industrial projects nationwide in New Zealand.

General Engineering

IFC Steel not only provides a comprehensive solution for all your steel needs, including everything from steel handrails to repairs for your boat trailer or multi-story architectural residence, but we also excel in maintenance and plant servicing. Our commitment extends beyond fabrication and welding; we ensure your facility remains in top condition with our expert maintenance servicing.

Additionally, our machine shop is equipped to handle a wide range of machining needs, further solidifying our position as your one-stop destination for all things steel. With our dedicated teams and facilities, IFC Steel guarantees excellence in every aspect of your project, from conception to completion.

Transport

With over 20 years of industry expertise, IFC Steel stands as your ultimate destination for your transport engineering needs. We have extensive Ute and Truck deck building experience, whether it is a flat deck, drop sides, H racks or a full truck mounted crane body.

Our Towbar manufacturing and fitting service is renowned in the Top of the South. We work closely with local mechanical engineers who provide the design and the NZTA LT400 certification for Class 1 COF and above. Whether you require a standard towbar, specialized fittings, or expert trailer fabrication and repair, trust IFC Steel to exceed your expectations every step of the way.

Frequently asked questions

Here you’ll find answers to some of the most frequently asked questions.

What is IFC Steel?

IFC Steel is a locally owned and operated business specialising in engineering solutions. We design, supply, fabricate, and erect structural steel for commercial and residential projects. We also cater to all your general engineering needs.

What services does IFC Steel offer?

We provide a comprehensive range of engineering services, including the design, fabrication, supply, and erection of structural steel. Our services cover both the commercial and residential markets. Specific services include manufacturing portal frames and structural beams, fabricating customised items, providing fully certified towbars and trailers, heavy transport bodies and repairs, agricultural equipment, and manufacturing, maintenance, and servicing of plant and machinery. We work with mild steel, stainless steel, and alloys.

Were you previously known by a different name?

Yes, IFC Steel was previously known as ET Engineering. We have rebranded due to continued growth and new business developments.

Where is IFC Steel located?

We are located at 128 Main Road, Hope 7020. This is our new and expanded premises.

Do you handle projects of all sizes?

Yes, at IFC Steel, we believe that no job is too big or too small. We are equipped to handle everything from manufacturing portal frames and structural beams to fully certified towbars and trailers, as well as handrails and gates, and multi-story structural steel buildings.

Can you assist with project design?

Absolutely. We are happy to assist with your design and requirements. We can sit with you to discuss your needs.

Do you provide quotes for your services?

Yes, we’re happy to provide you with an obligation-free quote.

Are your towbar installation services certified?

Yes, we have a dedicated towbar shop with fully certified welders specialising in all makes and models. We offer NZTA LT400 certified towbar service for Class 1 COF and above. We can also fabricate custom towbars and fittings.

What kind of experience does your team have?

Our team consists of qualified, certified, and experienced welder fabricators/fitter turners. We leverage decades of expertise across various engineering sectors.

What types of projects does IFC Steel undertake?

Our projects are diverse, ranging from handrails and gates to multi-story structural steel buildings, serving every industry within the community. We undertake structural steel projects for both residential and commercial clients. We also handle general engineering needs, including trailers, towbars, feature steel projects, as well as plant and machinery work.

What is your approach to quality and service?

We are committed to delivering the highest quality products that not only meet but exceed your expectations. We aim to establish a close working relationship with all our customers and provide a very high level of quality at competitive prices. We pride ourselves on a personable, professional service and a proven ability to meet tight deadlines. Clients have described our service as “impeccable” and the process “easy and smooth”.